Y Type Pressure Differential Valve

China Differential Pressure Relief Valve,Differential Pressure Control Valve,Hydraulic Pressure Differential Valve Supplier

Differential Pressure Relief Valve,Differential Pressure Control Valve,Hydraulic Pressure Differential Valve,Differential Pressure Regulating Valve

Pressure

differential valve is a fully automatic, hydraulic control valve. It is designed to maintain the differential pressure

between the two pipelines, so as to avoid the differential pressure exceeding

the system bearing range due to the action of other valves or the change of

flow demand. When the differential pressure increases, the valve

will open, and it will close automatically when the differential difference

drops.

Differential Pressure Relief Valve,Differential Pressure Control Valve,Hydraulic Pressure Differential Valve,Differential Pressure Regulating Valve A1-Best Trading Corporation , https://www.aone-best.com

Incremental Encoder vs Absolute Encoders in Closed-loop Feedback Systems

Certainly! Here's the rewritten content in English:

---

As a frequent topic in the world of position control, the terms "absolute" and "incremental" often arise. These terms refer to both the type of motion executed by a motor in programming terms and the kind of feedback device associated with the motor. This article focuses on the distinctions between an incremental closed-loop feedback system and an absolute closed-loop feedback system.

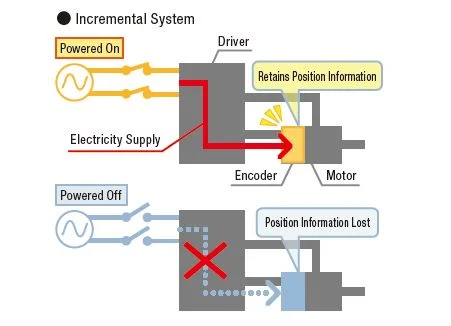

Let’s start with an overview of an incremental closed-loop feedback system. Below is an example:

When powered on, the optical encoder draws energy from the power supply and generates digital pulses as the motor shaft rotates. However, when power is turned off, the encoder loses its power source, and the pulse signal stops. At this point, the current position relative to a home reference point is lost. Re-establishing the same home position requires a homing routine, which can take valuable time away from normal operations.

### What is an Encoder?

An encoder is an electromechanical device attached to the motor shaft that uses digital pulses to monitor the motor's position. By counting the number of pulses emitted by the encoder, you can calculate the distance from the last known position, verifying whether the motor is at the target position.

Inside an encoder, there is a light emitter, a disc with slits around the rim, and a light receiver. As the encoder disc rotates with the motor shaft, the slits on the disc turn a static light source into flashes of light on the opposite side. The light receiver on the other side detects these light pulses and outputs a square wave pulse signal to the host controller. A pulse is generated for each step of rotation if the resolution matches between the encoder and the motor.

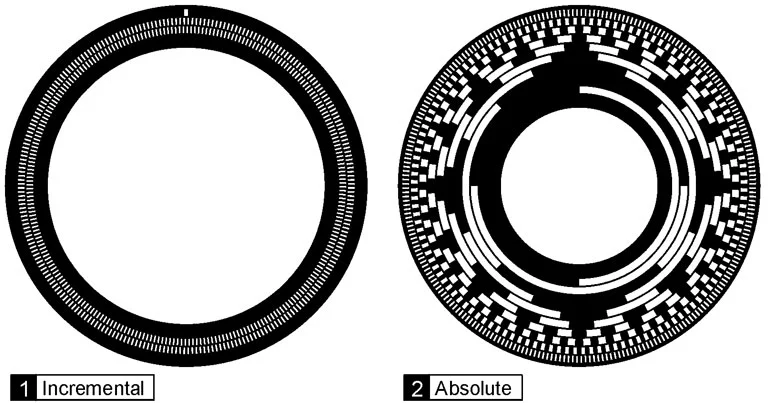

In an incremental closed-loop feedback system, an **incremental encoder** is typically used. An incremental encoder has two or three channels (A/B or A/B/Z) output. Each channel corresponds to a physical track of slits on the outer rim of the encoder disc (200 slits per A/B channel for a typical encoder). The slits for channels A and B are offset or out of phase by 90° to indicate the direction of movement. The third Z channel is a single slit on a separate track and can either mark a home position or count the number of revolutions. There is a diagram to clarify this concept later.

Since optical encoders rely on electricity to generate light pulses, they are not the best option if absolute position tracking is essential. In such scenarios, an absolute closed-loop feedback system is necessary.

---

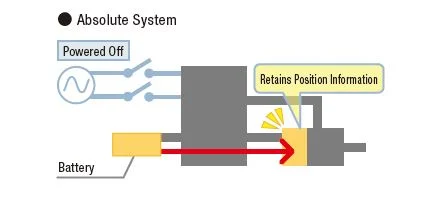

In an absolute closed-loop feedback system, a battery is added to ensure continuous power to avoid losing position information in case of power cycling. When the system powers on, the power supply charges the battery while energizing the motor, driver, and encoder to maintain position data. If the power supply is cut off, the driver and encoder will run on the battery until it depletes, resulting in the same issue as with incremental systems.

In an absolute closed-loop feedback system, an **absolute encoder** is commonly used. An absolute encoder operates similarly to an incremental encoder but has a more complex design, raising costs.

---

### Incremental Encoders vs Absolute Encoders

The key difference between an incremental encoder and an absolute encoder lies in the amount of information they can output. Structurally, an absolute encoder has more slits on its disc. In an incremental encoder, the disc has slits to produce light pulses, but each step produces the same pulse, making it non-unique to that position. On the disc of an absolute encoder, multiple tracks with different-sized slits exist. Each track has its own light emitter and receiver, allowing multiple bits of information to combine into unique "addresses."

For instance, imagine running both incremental and absolute systems simultaneously. If you move both motors into a position without looking at them, for the incremental system, you’d need to count the pulses produced from the home (0) position to determine how far the motor is from home. For the absolute encoder, since the "addresses" are unique, you would immediately know the motor's position by reading a binary number like 11111100, which equals 252 in decimal. With 8 bits of information, we can have up to 256 (2â¸) unique addresses. Many encoders used by servo motors offer 20 bits of information.

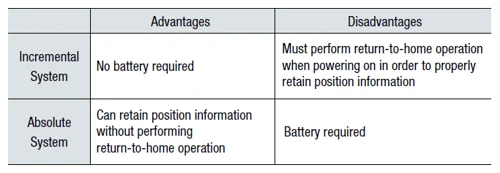

With an absolute system, the motor position is always known as long as power is available, enabling operations to resume at any position without performing a return-to-home operation. However, a battery is necessary, along with additional inventory and maintenance. Incremental systems do not require a battery, but position is lost once power is removed, necessitating a homing routine.

Below is a table highlighting the advantages and disadvantages of incremental and absolute systems:

---

### Is There an Alternative?

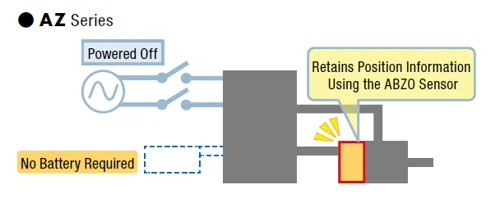

Both incremental and absolute systems depend on power, whether from a standard power supply or a battery. When power is depleted, position tracking is lost. Another technology gaining traction in the market is mechanical absolute encoders, magnetic encoders, or "ABZO" sensors. In this type of encoder, light emitters and receivers are replaced with segmented ring magnets and MR (magnetic resistive) sensors to determine absolute positions (see images below). To track multiple revolutions of unique, absolute positions, a series of gears is used.

Due to its design, this mechanical absolute feedback system is more robust than absolute encoders and can continuously track the absolute motor position even when power is off. Although it may offer lower resolution compared to 20-bit absolute encoders, its simpler design and robustness (against heat, humidity, and vibration) make it suitable for many position control applications. Differences in their operating principles mean encoder resolution benefits servo motors more than stepper motors.

---

Incremental systems (using incremental encoders) remain the most common choice for most applications due to the accuracy and cost-effectiveness of open-loop stepper motors. For absolute systems, the mechanical absolute encoder offers a low-cost, compact, and robust alternative for engineers looking to eliminate batteries from their machine designs.

The important thing is to select the one that best fits your application.

---

Oriental Motor’s **AZ Series** stepper motors and actuator systems feature mechanical absolute encoder technology to track absolute positions and a patented AlphaStep hybrid control system to prevent missed steps during operation. Position data can be sent to the host controller via I/O or through industrial network protocols like EtherCAT or EtherNet/IP.

The AZ Series is part of the **AlphaStep** family of closed-loop stepper motors and actuator systems. Watch the video below to learn more about the advantages offered by the AZ Series.

---

These resources provide further insights into the AlphaStep family:

- [A Brief Overview of the AlphaStep Family](http://bsg-i.nbxc.com/blog/8c853f2190fad58c1c95de119bde5402.png)

- [The AZ Advantage: Eliminating External Sensors](http://bsg-i.nbxc.com/blog/f3d1e749623c2132f681aecfc36caeeb.png)

- [Development of the Battery-Free Multi-Rotation Absolute Mechanical Encoder](http://bsg-i.nbxc.com/blog/7fd5b1efc7517c7cb86d9b17cdb3f6fc.png)

---

Choose the solution that best meets your needs!