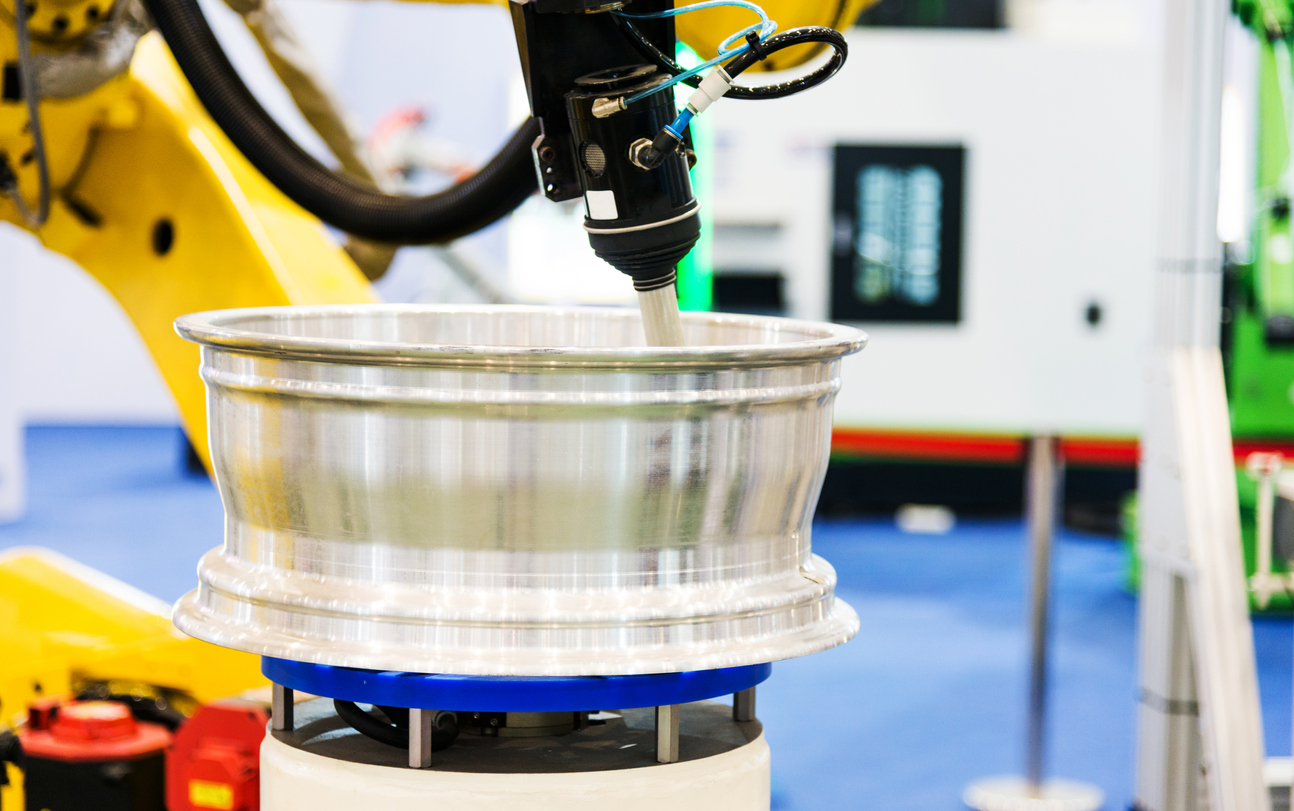

When it comes to boosting productivity in manufacturing facilities, robotic welding has proven itself as a game-changer compared to traditional manual welding methods. However, just because robots are programmed and operational doesn’t mean their potential is fully realized. There’s always room for optimization, and manufacturers who take proactive steps can significantly reduce costs while enhancing overall efficiency. With so many variables involved in robotic welding, here are seven practical strategies to help you streamline your operations and cut costs without compromising quality. Robotic welding systems are sophisticated pieces of machinery that demand careful attention and regular upkeep. By implementing the right practices, you can ensure that your robotic welding processes run smoothly and efficiently, minimizing unnecessary expenses. Invest in peripheral tools: Accessories like reamers, contact tips, wire cutters, and inspection tools play a crucial role in maintaining the integrity and performance of your robotic welding setup. Neglecting these components can lead to costly inefficiencies and equipment failures. Utilize these peripherals strategically to enhance productivity and reduce downtime. Streamline filler metal packaging: Frequent changes in filler metal packages disrupt workflow and eat into valuable production time. Optimize the size of your filler metal containers so they last several days, reducing the frequency of changeovers and keeping operations running smoothly. Maintain optimal wire feeding: Poor wire feeding is a common issue that can halt production and cause irreparable damage to your equipment. Regularly inspect and adjust wire feeding mechanisms to prevent blockages and ensure consistent performance. Prolong contact tip lifespan: Proper maintenance of contact tips not only extends their usable life but also reduces the frequency of changeovers. This, in turn, improves overall productivity and cuts down on inventory costs. Protect reamer blades: Broken blades in reamers increase maintenance costs and slow down production. Make sure your nozzles are correctly positioned to avoid damaging the cutting blades, which helps preserve the longevity of your tools. Embrace operator training: Many reputable robot integrators offer comprehensive training programs designed to keep operators up-to-date with the latest safety protocols and best practices. Encouraging continuous learning ensures that your robotic welding systems operate at maximum capacity. Adopt preventive maintenance routines: No matter how well-built your equipment is, it will eventually show signs of wear and tear. Implementing a proactive maintenance schedule helps identify potential issues before they become serious problems, extending the lifespan of your assets and minimizing unplanned downtime. By adopting these seven strategies, you’ll be well on your way to maximizing the benefits of robotic welding. Remember, the key lies in consistently monitoring and refining your processes to achieve long-term success. If you're interested in taking your robotic welding capabilities to the next level, consider exploring advanced integration solutions offered by leading providers like Genesis Systems Group. Their expertise in robotic welding technology can help you unlock new levels of productivity and profitability. Manufacturers today face increasing pressure to deliver high-quality products faster and more cost-effectively than ever before. With the right approach, robotic welding can help meet these demands while providing a competitive edge. Whether you're a small business or a large enterprise, optimizing your robotic welding processes is an investment worth making. For instance, imagine being able to reduce changeover times by even just 15 minutes per day. Over the course of a year, that could translate into hundreds of additional hours of productive work—hours that could be used to take on new projects, expand your product line, or simply meet customer demand more effectively. Additionally, focusing on preventive maintenance not only extends the life of your equipment but also boosts morale among employees. When workers know that their machines are reliable and well-maintained, they feel more confident and motivated to perform at their best. Finally, don't underestimate the importance of staying informed about emerging trends and technologies in the field of robotics. Attending industry conferences, joining professional associations, and networking with peers can provide valuable insights and open doors to collaboration opportunities that might otherwise go unnoticed. In conclusion, whether you're just starting out with robotic welding or looking to refine existing practices, there's always something new to learn and implement. By following these guidelines and staying proactive, you'll be better equipped to handle challenges, seize opportunities, and ultimately thrive in today's dynamic marketplace. A Wood Fired Pizza Oven is a timeless piece of culinary equipment, revered for its ability to produce pizzas with unparalleled flavor and texture. Constructed from robust materials like brick, clay, or stone, these ovens are designed to withstand intense heat while providing even cooking surfaces. The heart of a wood fired oven is its domed interior, which allows for optimal heat retention and circulation, ensuring that each pizza is cooked to perfection. The unique appeal of a wood fired pizza oven lies in its ability to impart a distinct, smoky flavor to the pizza, something that cannot be replicated by gas or electric ovens. The high temperatures, often reaching up to 900 degrees Fahrenheit (482 degrees Celsius), create a crispy, blistered crust while keeping the toppings perfectly melted and caramelized. The process of building and maintaining the fire adds an element of artistry and tradition, connecting the cook to centuries of pizza-making heritage. Using a wood fired oven involves skill and patience. The fire must be carefully built and maintained to achieve the desired temperature. The pizza, typically cooked directly on the oven's hot surface, requires careful monitoring and occasional rotation to ensure an even bake. This hands-on approach not only enhances the cooking experience but also results in pizzas with a rustic, artisanal quality. Wood fired pizza ovens are more than just functional cooking tools; they are also beautiful additions to any kitchen or outdoor space. Their classic design and warm, glowing interior create a focal point for gatherings, drawing friends and family together around the promise of delicious, homemade pizza. The process of making pizza in a wood fired oven becomes a communal activity, filled with anticipation and enjoyment. Wood Fired Pizza Oven bbq,outdoor Wood Fired Pizza Oven,Pizza oven bbq outdoor,portable Wood Fired Pizza Oven,folding Wood Fired Pizza Oven gftop , https://www.gftopgrill.com7 Ways to Enhance Efficiency and Cut Costs in Robotic Welding Operations

Maximizing Efficiency in Robotic Welding