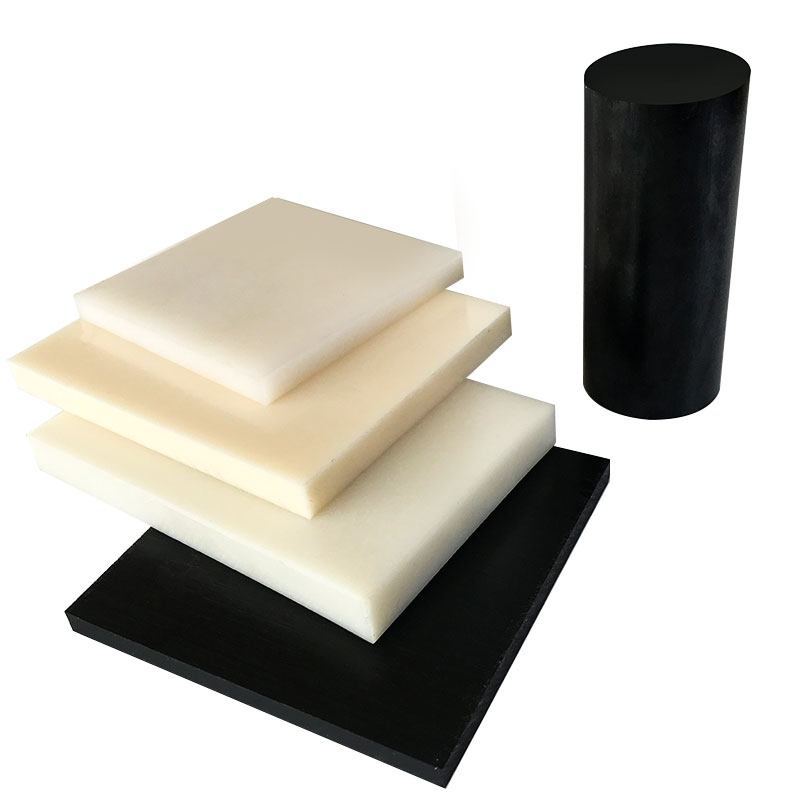

HONYESD®POM Antistatic sheet rod is a kind of antistatic materials which is made by POM acetal. The working temperature is -40-100℃.And HONYESD®POM provided stable and uniform antistatic value. The surface and volume resistivity value is 106-109Ω. And the antistatic value will not changed after machining or surface grinding. This materials is suitable for automatic lathe machining, especially suitable for the manufacture of precision parts. Grade A ESD Black /Ivory sheet ,Delrin sheet ,POM Sheet Anti-static esd white black POM Sheet/Rod Acetal, Delrin Sheets, ESD POM Plate ESD Anti-static POM delrin Acetal sheet and rods plastics sheet and rod manufacturer available stock Volume resistivity value 106-109Ω HONYESD®POM Antistatic Rod Sheet Advantages: 1. Excellent abrasion and creep resistance property; 2. High dimensional and shape stability; 3. Retains toughness under low temperature (-40°C); 4. Resistant to organic solvents; Insoluble under normal temperature; 5. Thermal deformation temperature is close to that of PC, PTFE and nylon; 6. High compressive strength, second only to glass fiber; 7. Good sliding property; wear resistant; non-water absorbent; HONYESD®POM Antistatic Rod Sheet Disadvantages: 1. Not resistant to acids, especially to mineral acids; 2. Not resistant to UV; 3. Not self-extinguishing, and thus must be kept away from fire; 4. Not resistant to impact. HONYESD®POM Antistatic Rod Sheet Applications: 1. Sliding parts: bearing and lining, roller, conveyor chain; 2. Precision mechanical components: gear, cam, coupler, idler roller; 3. Waterproof components: impeller, pump case, gasket; 4. Electrical parts: guide pulley, spring lock; 5. Fixture, lever, handle, knob and other jig materials Antistatic Esd Pom,Semitron®ESd 225 POM,Acetal Antistatic Esd Pom Sheet,ESd POM,antistatic POM Hony Engineering Plastics Limited , https://www.honyplastic.com

Name

ESD antistatic POM polyoxymethylene sheet

Brand

HONYESD

Color

Black , Ivory ( Beige natural )

Size

610 x 1200mm 1000 x 2000mm 1000 x 3000mm 1220x2440mm

Thickness

0.5-100mm

Type

Sheet Rod Profile Tube

The working temperature

-40℃-100℃

Counter Weight Piece of Electricity Power Fitting

Counter Weight Piece

Trade Mark: Goliker

Manufacturing Process: Hot Forging

Material: Carbon Steel, Alloy Steel, and More

Size: Customized Based on Drawing

Standards: DIN, ASTM, BS, JIS, GB, AISI, ANSI, GOST

Heat Treatment: Tailored to Mechanical Requirements

Machining: Optional

Surface Treatment Options: Plain, Sand Blasted, Hot-Dipped Galvanized, Zinc Plated, Dacromet, Black, Painted, Powder Coated

Our product range includes container accessories, railway components, construction forgings, hardware tools, and power fittings. With a team of over 10 engineers and technical staff, plus more than 50 skilled forging workers and managers, we are equipped with state-of-the-art production facilities. We operate a variety of forging equipment, including 300-ton, 400-ton, 630-ton, and 1,000-ton electric screw presses, along with electric heat treatment furnaces. Additional machinery includes horizontal lathes, CNC lathes, machining centers, drilling machines, grinders, cleaning systems, and stamping machines. This full-service approach allows us to provide comprehensive solutions from forging to final processing. Our annual production capacity exceeds 10,000 tons, and we maintain strong partnerships with major enterprises both domestically and internationally.