Production Line With Clapboard Clapboard,equipment,line ChangZhou FENGJU Machinery Equipment CO., LTD , https://www.fengjumachinery.com

Carbon Output Calculation of Electric Motors

Sure! Here's the rewritten content in English:

---

Increasing power efficiency and minimizing carbon footprints has become a global trend. Are you aware of how to calculate the carbon dioxide (COâ‚‚) emissions generated by your electric motors and which types of motors produce fewer emissions?

To calculate a motor's CO₂ emissions, you’ll need two key pieces of information:

1. Power consumption (in kWh)

2. The COâ‚‚ emission factor (in kgCOâ‚‚/kWh) provided by your electricity provider.

Using the following formula, you can estimate a motor's COâ‚‚ emissions:

**■Formula for Calculating a Motor’s CO₂ Emissions**

Motor’s CO₂ emissions (kgCO₂)

= Motor's power consumption (kWh) × CO₂ emission factor (kgCO₂/kWh)

For example, let’s consider a 200-watt AC motor paired with an inverter. If it operates for 12 hours a day over 300 working days in a year, with a CO₂ emission factor of 0.470 kgCO₂/kWh, the annual CO₂ emissions would be approximately 521 kgCO₂.

**Power consumption (1,109 kWh/year) × CO₂ emission factor (0.470 kgCO₂/kWh) = CO₂ emissions (~521 kgCO₂)**

**Conditions:**

-Calculated at 12 hours of daily operation, 300 operating days annually, and a COâ‚‚ emission factor of 0.470 kgCOâ‚‚/kWh.

-Example refers to a standard 200-watt BH Series 3-phase AC induction motor with an inverter.

However, if you’re looking for even greater efficiency, a brushless (DC) motor might be a better choice.

If you switch to a brushless motor with the same 200-watt output, you could reduce the annual CO₂ emissions to approximately 386 kgCO₂ under the same conditions. That’s around 25% less than an AC motor!

**Power consumption (821 kWh/year) × CO₂ emission factor (0.470 kgCO₂/kWh) = CO₂ emissions (~386 kgCO₂)**

**Conditions:**

-Calculated at 12 hours of daily operation, 300 operating days annually, and a COâ‚‚ emission factor of 0.470 kgCOâ‚‚/kWh.

-Example refers to a 200-watt BMU Series brushless motor.

Here’s a quick comparison:

| **Motor Type** | **Power Consumption (kWh/year)** | **COâ‚‚ Emissions (kgCOâ‚‚/year)** |

|-------------------------|----------------------------------|--------------------------------|

| AC Motor + Inverter | 1,109 | 521 |

| Brushless Motor + Driver| 821 | 386 |

This means that by replacing a 200-watt AC motor with an inverter with a brushless motor of equivalent specifications, you can reduce CO₂ emissions by approximately 135 kgCO₂ annually. That’s equivalent to the CO₂ emissions produced by one refrigerator per year!

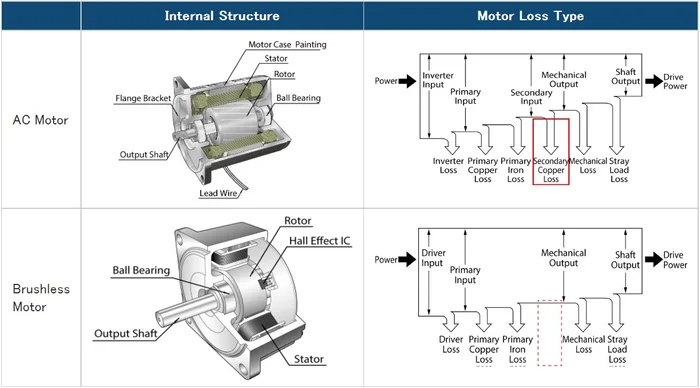

Why are brushless motors more efficient? Brushless motors use permanent magnets to enhance magnetic flux, resulting in lower losses compared to AC motors. They don’t experience secondary copper losses, making them far more efficient. This efficiency not only reduces energy usage but also decreases the motor’s size and weight, conserving valuable natural resources.

Electrically commutated (EC) fans equipped with brushless motors can also play a role in saving energy. When comparing different speed control technologies, brushless motors offer numerous advantages over traditional AC motors.

**Takeaways:**

- A motor’s CO₂ emissions can be calculated by multiplying its power consumption (kWh) by the CO₂ emission factor (kgCO₂/kWh).

- High-efficiency brushless motors are excellent tools for reducing COâ‚‚ emissions.

- Switching from an AC motor to a brushless motor can decrease annual COâ‚‚ emissions by an amount equivalent to one refrigerator.

To learn more about products that can help reduce energy consumption and carbon emissions, check out our **carbon neutrality page**.

For additional tips on resource-efficient small motors, visit our resource-saving page.

If you’d like a consultation on achieving carbon neutrality, consider scheduling a technical seminar with us.

---

I hope this helps! Let me know if you'd like any further adjustments.