Inspection Tools: A Guide to the Essential Equipment Used by Inspectors Daily

Inspection tools are vital for collecting accurate data to ensure the proper maintenance of assets. This guide provides an in-depth look at the different types of tools inspectors use in their work.

Inspection tools play a crucial role in gathering the information needed to assess the condition and maintenance status of various assets. Whether it's visual, thermal, or thickness-related data, the right tools make all the difference in ensuring safety and efficiency.

The type of data required for an inspection determines the specific tools that will be used. Once collected, this data is analyzed to identify any potential issues and determine necessary maintenance actions.

Understanding Inspection Tools vs. Inspection Equipment

In this article, inspection tools refer to the actual devices and instruments used to collect data directly. These could include a thickness gauge for assessing wall integrity or a drone equipped with a camera to capture remote visual data from hard-to-reach areas.

Inspection equipment, on the other hand, refers to the support systems that help inspectors access data or perform their tasks more effectively. Examples include tool belts, scaffolding, or ropes used for climbing into confined spaces.

[Related read: Confined Space Equipment: A Guide]

Whether inspecting a large industrial boiler or a small HVAC unit, the process remains consistent:

- Inspectors gather data using appropriate tools.

- They analyze the data using industry-specific methods.

- Based on the findings, they decide on necessary maintenance actions.

While the basic concept is simple, the variety of tools used can be quite extensive. They are typically categorized based on the type of data they collect or the method of data collection, such as aerial or ground-based robotics.

Now let’s explore the different types of inspection tools in detail.

Â

Cameras and Visual Data Collection Tools

Visual data is one of the most frequently needed types of information during inspections. Cameras are the go-to tool for capturing this data, but not all cameras are suitable for every inspection.

The choice of a camera depends on the specific data requirements. If the camera can capture the necessary details at a usable quality, it's the right tool for the job.

Some common visual data collection tools include:

- Digital cameras: Available in various qualities and costs, these are essential for capturing high-resolution images in different lighting conditions.

- Borescopes: These allow inspectors to view inaccessible areas, making them ideal for internal inspections of pipes, engines, and more.

- Video and digital microscopes: Useful for close-up inspections, these tools provide detailed views of small components or surfaces.

- Videoscopes: Designed for remote inspections, videoscopes have cameras embedded in their tips for accessing tight spaces.

- CCTV systems: Often used in sewer and pipe inspections, CCTV allows remote viewing of underground structures.

A borescope being used to inspect a car engine

A borescope being used to inspect a car engine

NDT Sensors and Testing Methods

While visual data is commonly used, there are many other types of data that may be required for a thorough inspection. Each of these requires specific sensors or NDT (Non-Destructive Testing) methods to collect the necessary information.

Ropes and Drones Case Study

A great example of how multiple tools and methods can be combined is seen in an inspection conducted by Premium Inspection & Testing. To avoid building scaffolding, they used a mix of drones and rope access to collect all the required data efficiently.

Photo credit: Premium Inspection & Testing

Photo credit: Premium Inspection & Testing

Here are the steps they followed:

1. Visual data collected by drone – Using Flyability’s Elios 2, they captured internal visuals of the coker.

2. Corrosion, pitting, and other data collected by rope access – They used Creaform 3D scanning, phased array testing, and liquid penetrant testing to evaluate the structure.

This approach saved the client $250,000 while providing complete data coverage.

Examples of NDT Sensors and Methods

- Thermal sensors: Detect heat leaks or hot spots in structures.

- Ultrasonic sensors: Use sound waves to detect material defects.

- Radiography: Uses X-rays or gamma rays to find surface imperfections.

- Eddy current testing: Measures electrical currents to detect flaws in materials.

For more information on NDT methods, check out our comprehensive guide.

Robots in Inspection

There are three main categories of robotic solutions used in inspections:

- Drones / Aerial Robots

- Ground-Based Robots

- Submersible / Underwater Robots

Drones / Aerial Solutions

Over the past few years, drones have become a popular tool for remote data collection in industrial settings. Remote Visual Inspection (RVI) tools like drones allow inspectors to collect data without entering hazardous environments.

These tools can also carry thermal or other specialized sensors, expanding their capabilities as technology advances.

Why Use RVI Tools?

- Safety: Reduces the need for personnel to enter dangerous areas.

- Savings: Can cut inspection costs by up to 90%.

- Reduced Downtime: Speeds up the inspection process significantly.

Indoor vs. Outdoor Drones

Indoor drones are designed for confined spaces, like boilers or tanks. They often feature protective cages to prevent damage during collisions. For example, Flyability’s Elios 3 is built for safe operation in tight areas.

Outdoor drones, such as DJI’s Matrice 300, are made for larger, open environments and don’t require the same level of collision resistance.

DJI's Matrice 300, an outdoor drone commonly used in inspections

DJI's Matrice 300, an outdoor drone commonly used in inspections

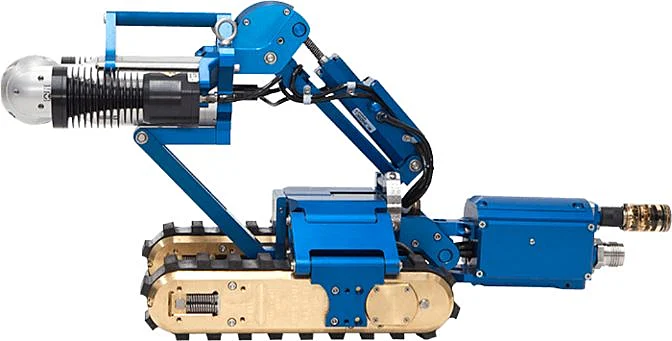

Ground-Based Robotic Solutions

Ground-based robots offer similar benefits to drones, improving safety and reducing costs. Some examples include:

Inuktun MaggHD

The Inuktun MaggHD is a magnetic crawler used for remote inspections in hazardous areas.

The Inuktun MaggHD is a magnetic crawler used for remote inspections in hazardous areas.

Deep Trekker DT320

The Deep Trekker DT320 is a mini pipe crawler for inspecting sewers and other difficult-to-access areas.

The Deep Trekker DT320 is a mini pipe crawler for inspecting sewers and other difficult-to-access areas.

Inuktun Versatrax 150

The Inuktun Versatrax 150 is a long-range crawler for tank and pipeline inspections.

The Inuktun Versatrax 150 is a long-range crawler for tank and pipeline inspections.

Submersible Robotics

Submersible robots are increasingly used in underwater inspections. These tools enhance safety by eliminating the risks associated with diving operations.

MASKI+

The Maski+ ROV is used by HydroQuebec to inspect dams in turbulent or deep waters.

INTERO TANK EXPLORER

The Intero Tank Explorer is an intrinsically safe robot used in petrochemical storage tanks to detect thickness inconsistencies and provide real-time images.

Advancements in Robotics

New robotic technologies are emerging to address previously inaccessible or hazardous inspection sites. Some robots even come equipped with tools to fix identified issues, such as water-jet cutters or UV-curable patches.

Measuring Devices

Measuring devices are essential for collecting precise measurements of dimensions, depth, and angles. Many of these tools are handheld and do not require electricity, such as calipers.

Common measuring tools include:

- Engineering squares: Used to check perpendicularity and draw straight lines.

- Protractors: Measure angles between surfaces.

- Levels: Determine the inclination of a surface.

- Calipers: Measure external, internal, and depth dimensions.

- Gages: Compare objects to standard sizes for accuracy.

- Micrometers: Measure very small distances with high precision.

Inspection Software

With the increasing volume of data collected during inspections, managing and analyzing this information has become a growing challenge. That’s where inspection software comes in—offering improved data collection and management solutions.

Improved Data Collection Software

Software like Flyability Inspector 3.0 includes 3D modeling features, allowing inspectors to create quick models of inspected assets and mark defect locations efficiently.

Data Management Tools

Modern software solutions use AI and machine learning to process large volumes of data quickly, making it easier for inspectors to identify issues and take action.

As these technologies continue to evolve, they will play a key role in improving the speed, accuracy, and safety of inspections across industries.

Titanium Mesh Anode,Titanium Hex Wire Mesh,Platinized Titanium Mesh Anode,Titanium Anode Mesh Basket

Baoji Qiyuexin Metal Material Co., Ltd. , https://www.qyxtitanium.com