Chain blocks are essential tools in a wide range of industries, offering a dependable and efficient way to lift and move heavy objects. Whether you're working on a construction site, in a manufacturing facility, or even tackling a home project, having a solid understanding of chain blocks is key to ensuring safe and effective lifting operations.

Understanding the basics of chain blocks

What is a chain block?

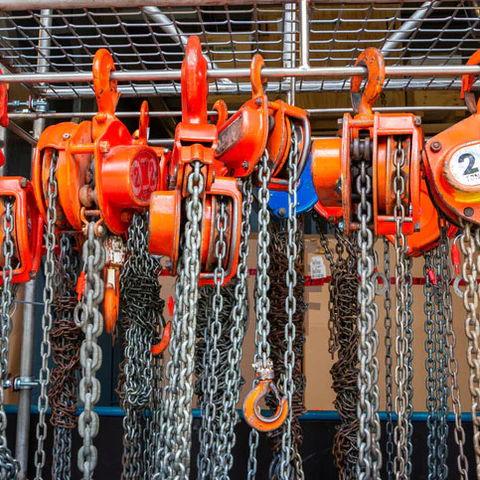

A chain block, also known as a chain hoist, is a mechanical device designed to lift heavy loads by applying force through a chain. It typically includes a system of pulleys and gears that allow for controlled and smooth lifting. These devices are commonly used in environments where precise and reliable lifting is required.

Key components of a chain block

Chain blocks consist of several important parts, including hooks, load chains, gears, and braking systems. The hooks provide a secure point of attachment for the load, while the load chains are made from high-strength steel to support the weight being lifted. Gears help transfer the force applied by the user, and braking mechanisms ensure the load stays in place once lifted.

Each component plays a vital role in the overall performance and safety of the chain block. The gears multiply the force applied by the operator, making it easier to lift heavier objects. Meanwhile, the braking system acts as a critical safety feature, preventing the load from slipping or falling unexpectedly.

Â

Different types of chain blocks

Manual chain blocks

Manual chain blocks are the most widely used type, operated entirely by hand. They are cost-effective, easy to use, and ideal for light to medium lifting tasks. These blocks are often found in workshops, construction sites, and maintenance areas where power sources may not be readily available.

One of the biggest advantages of manual chain blocks is their simplicity and portability. Since they don’t require electricity or hydraulics, they can be used in remote locations or outdoor settings where other lifting equipment might not be practical. This makes them a versatile option for many different applications.

Electric chain blocks

Electric chain blocks are powered by electricity and are ideal for lifting heavier loads with greater efficiency. These blocks use electric motors to provide consistent and controlled lifting, making them popular in industrial settings such as factories, warehouses, and large-scale construction projects.

Electric models offer smoother operation compared to manual ones, reducing the risk of sudden jerks or drops. This makes them particularly useful when handling delicate or expensive items that require careful handling. Additionally, they reduce physical strain on operators, making them a preferred choice for frequent lifting tasks.

How chain blocks work

The mechanics of lifting

When a chain block is in use, the operator pulls the chain, which wraps around the gears and lifts the load. As the gears turn, the chain moves through the pulleys, allowing the load to be raised with less effort than lifting manually. This mechanical advantage makes it possible to lift heavy objects with minimal physical strain.

Chain blocks come in various sizes and capacities, each designed for specific lifting needs. The durability of the gears and the smoothness of the pulley system are crucial for efficient operation. High-quality materials like steel are often used to ensure long-lasting performance under heavy use.

Safety mechanisms in chain blocks

Safety is a top priority in chain block design. Most models include features such as overload protection, which prevents the device from lifting beyond its rated capacity, and automatic brakes that engage when the lifting stops or the load is stationary. These features help prevent accidents and protect both the operator and the load.

Additionally, many chain blocks have a safety latch on the hook to prevent accidental slippage during lifting. Regular maintenance and inspections are also essential to ensure all safety features remain functional and the chain block continues to operate reliably over time.

Selecting the right chain block

Determining your lifting needs

Before choosing a chain block, it’s important to evaluate your lifting requirements. Consider the weight of the load and the height you need to lift. Selecting a chain block with the appropriate lifting capacity and height ensures safe and efficient operations.

It's also wise to consider future needs when selecting a chain block. If you anticipate an increase in load size or frequency of use, choosing a model with a slightly higher capacity can save you from needing to replace the equipment later on.

Evaluating chain block quality and safety features

When purchasing a chain block, prioritize quality and safety. Look for models that meet international safety standards and have been thoroughly tested. Features like load limiters, corrosion resistance, and ease of maintenance can significantly impact the longevity and reliability of the device.

Additionally, check for certifications from reputable organizations to confirm the product meets strict quality and safety criteria. These certifications can give you confidence that the chain block has been manufactured to high standards and is built to last.

By gaining a deeper understanding of how chain blocks work, their different types, and how to choose the right one for your needs, you can make more informed decisions when using these valuable lifting tools. Always remember that safety should be your top priority, and regular maintenance is essential for long-term performance and reliability.

wallbox charger,tesla wall box,electric wallbox, ev wallbox

Xuchang Shuoniu New Energy Technology Co., Ltd. , https://www.shoniu.com