Seamless carbon steel pipes are known for their strength and durability due to the absence of joints, which reduces potential weak points. Their consistent mechanical properties along the entire length make them ideal for applications where reliability is critical. Additionally, they offer better resistance to high temperatures because there are no welds that could potentially weaken the structure.

The precise dimensions and thickness of seamless pipes ensure predictable performance in various environments, making them a preferred choice for demanding applications.

In contrast, welded carbon steel pipes may have reduced strength and durability compared to seamless ones. This is largely due to the welding process itself, which can cause changes in the microstructure and mechanical properties near the weld area, leading to lower toughness and resistance to stress.

Welded pipes might also exhibit surface imperfections such as weld beads or heat-affected zones, which often require additional finishing or cleaning to meet specific requirements.

Seamless carbon steel pipes are commonly used in:

- High-pressure applications

- Hydraulic systems

- Critical liquid transport

Welded carbon steel pipes are typically used in:

- Medium pressure and temperature applications

- Non-corrosive fluid transport

Manufacturing Process

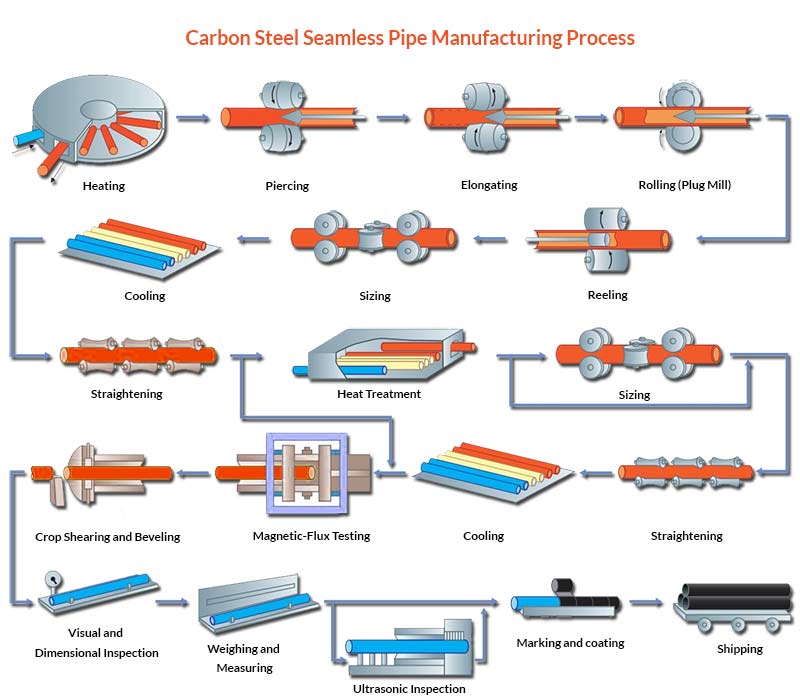

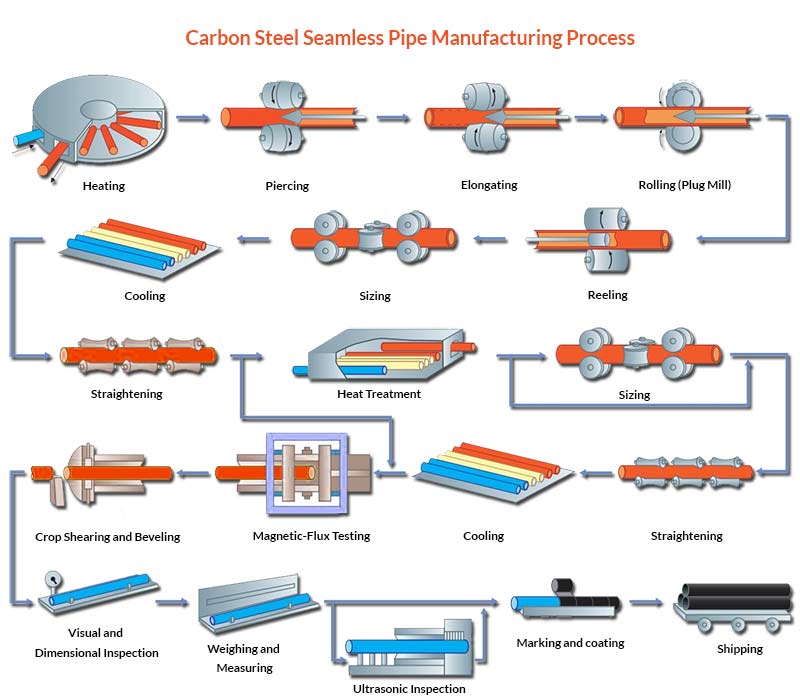

Seamless carbon steel pipes are produced by extruding a solid steel bar to create a hollow pipe, ensuring no joints or welds. This method results in a uniform design and structure.

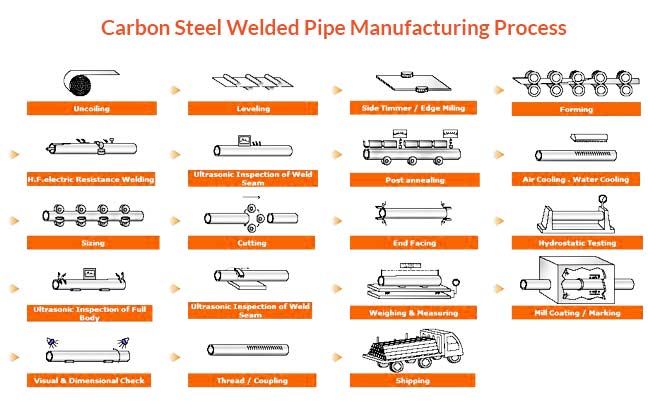

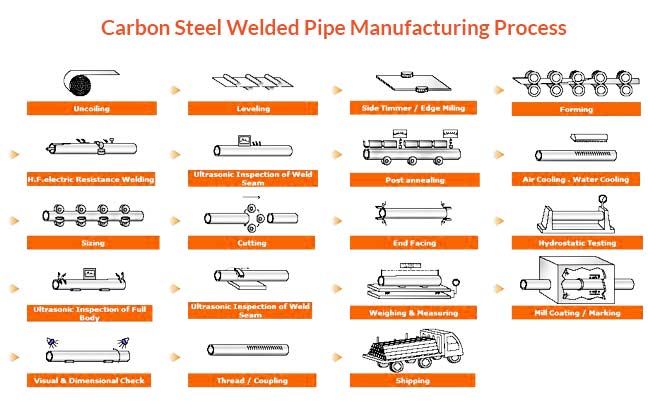

Welded carbon steel pipes are manufactured by rolling a flat plate into a cylindrical shape and then welding it. Common methods include longitudinal (LSAW) and spiral (SSAW) welding.

Why Choose?

Seamless pipes are ideal for high-pressure environments where strength and reliability are crucial. They are often used in critical industries like oil and gas, chemical processing, and power generation.

Welded pipes are cost-effective and easier to manufacture, making them suitable for medium-pressure and temperature applications.

Table of contents

- Carbon Steel seamless and welded pipe manufacturing process

- Seamless vs Welded Carbon Steel Pipe Specification

- Carbon steel Welded and seamless pipe equivalent

- Tolerances for hot finished seamless pipe

- Tolerances for cold drawn welded tubes

- Carbon Steel seamless and welded pipes chemical composition

- CS Welded and Seam Pipe mechanical properties

- List of documents to import Low Temp Welded Pipe

- A106 Seamless and Welded Pipe Schedule

- CS Welded and Seamless Pipe International Standard

- Hot finished welded type tubes sizes in mm

- Difference between seamless pipe and erw pipe

- Maximum Allowed Stress of DIN EN 10220 seamless steel pipes

- Low Temp Seamless Pipe Charpy V-Notch Impact Tests

- Hot Forming and Heat Treatment of CS ERW and Seamless pipe

- List of machinery to produce seamless pipe

- List of machinery to produce welded pipe

- Testing for Seam pipe and ERW Pipe

List of Seamless Carbon Steel Pipe grades for high-temperature service, check uses and manufacturing process of CS SMLS and Welded pipes

Carbon Steel seamless and welded pipe manufacturing process

Carbon steel seamless pipe manufacturing process

Carbon steel welded pipe manufacturing process

Check Carbon Steel welded and seamless pipe specifications, equivalent, tolerances, and properties

Seamless vs Welded Carbon Steel Pipe Specification

Carbon steel Welded and seamless pipe equivalent

| DIN |

BS |

NFA |

ASTM |

| DIN 17175 Grade 17 Mn 4 |

NFAA 49-213 Grade TU 48-c |

ASTM A106 Grade C |

ASME SA 106 Grade C |

Tolerances for hot finished seamless pipe

Outside Diameter Range

(inches) |

Wall Percent

of O.D. |

Unannealed or Stress

Relief Annealed |

Oil Quenched &

Tempered |

Soft Annealed or

Normalized |

| O.D. Inches |

I.D. Inches |

O.D. & I.D. |

O.D. Inches |

I.D. Inches |

| Plus |

Minus |

Plus |

Minus |

Plus/Minus |

Plus |

Minus |

Plus |

Minus |

| Up to 0.499 |

All |

0.004 |

0.000 |

|

|

0.005 |

0.005 |

0.002 |

|

|

| 0.500-1.699 |

All |

0.005 |

0.000 |

0.000 |

0.005 |

0.005 |

0.007 |

0.002 |

0.002 |

0.007 |

| 1.700-2.099 |

All |

0.006 |

0.000 |

0.000 |

0.006 |

0.008 |

0.006 |

0.005 |

0.005 |

0.006 |

| 2.100-2.499 |

|

0.007 |

0.000 |

0.000 |

0.007 |

0.009 |

0.008 |

0.005 |

0.005 |

0.008 |

| 2.500-2.899 |

All |

0.008 |

0.000 |

0.000 |

0.008 |

0.010 |

0.009 |

0.005 |

0.005 |

0.009 |

| 2.900-3.299 |

All |

0.009 |

0.000 |

0.000 |

0.009 |

0.012 |

0.011 |

0.005 |

0.005 |

0.011 |

| 3.300-3.699 |

All |

0.010 |

0.000 |

0.000 |

0.010 |

0.013 |

0.013 |

0.005 |

0.005 |

0.013 |

| 3.700-4.099 |

All |

0.011 |

0.000 |

0.000 |

0.011 |

0.014 |

0.013 |

0.007 |

0.010 |

0.010 |

| 4.100-4.499 |

All |

0.012 |

0.000 |

0.000 |

0.012 |

0.015 |

0.014 |

0.007 |

0.011 |

0.011 |

| 4.500-4.899 |

All |

0.013 |

0.000 |

0.000 |

0.013 |

0.017 |

0.016 |

0.007 |

0.012 |

0.012 |

| 4.900-5.299 |

All |

0.014 |

0.000 |

0.000 |

0.014 |

0.018 |

0.018 |

0.007 |

0.013 |

0.013 |

| 5.300-5.549 |

All |

0.015 |

0.000 |

0.000 |

0.015 |

0.019 |

0.020 |

0.007 |

0.014 |

0.014 |

| 5.550-5.999 |

Under 6 |

0.010 |

0.010 |

0.010 |

0.010 |

0.025 |

0.018 |

0.018 |

0.018 |

0.018 |

| 6 to 7 1/2 |

0.009 |

0.009 |

0.009 |

0.009 |

0.023 |

0.016 |

0.016 |

0.016 |

0.016 |

| Over 7 1/2 |

0.018 |

0.000 |

0.009 |

0.009 |

0.023 |

0.017 |

0.015 |

0.016 |

0.016 |

Tolerances for cold drawn welded tubes

Size Range

Inch (mm) |

OD Tolerance Inch (mm) |

| Over |

Under |

| Up to 2.999 (76.17) |

0.020 (0.51) |

0.020 (0.51) |

| 3.000-4.499 (76.20-114.27) |

0.025 (0.64) |

0.025 (0.64) |

| 4.500-5.999 (114.30-152.37) |

0.031 (0.79) |

0.031 (0.79) |

| 6.000-7.499 (152.40-190.47) |

0.037 (0.94) |

0.037 (0.94) |

| 7.500-8.999 (190.50-228.57) |

0.045 (1.14) |

0.045 (1.14) |

| 9.000-10.750 (228.60-273.05) |

0.050 (1.27) |

0.050 (1.27) |

| 10.750 and larger |

1% |

1% |

Carbon Steel seamless and welded pipes chemical composition

ASTM A53

| Values in % |

Type S

(Seamless) |

Type F

(Furnace Weld) |

Type E

(ERW) |

| A53 |

Grade A |

Grade B |

Grade A |

Grade A |

Grade B |

| Manganese |

0.95 |

1.2 |

1.2 |

0.95 |

1.2 |

| Carbon |

0.25 |

0.3 |

0.3 |

0.25 |

0.3 |

| Sulfur |

0.045 |

0.045 |

0.045 |

0.045 |

0.045 |

| Phosphorous |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

| Nickel |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Copper |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Molybdenum |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

| Chromium |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

| Vanadium |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

ASTM A106

| Element |

Mn |

C

max |

S

max |

P

max |

Cr

max (3) |

Si

min |

Mo

max (3) |

Cu

max (3) |

V

max (3) |

Ni

max (3) |

| Grade A |

0.27-0.93 |

0.25 (1) |

0.035 |

0.035 |

0.40 |

0.10 |

0.15 |

0.40 |

0.08 |

0.40 |

| Grade B |

0.29-1.06 |

0.30 (2) |

0.035 |

0.035 |

0.40 |

0.10 |

0.15 |

0.40 |

0.08 |

0.40 |

| Grade C |

0.29-1.06 |

0.35 (2) |

0.035 |

0.035 |

0.40 |

0.10 |

0.15 |

0.40 |

0.08 |

0.40 |

ASTM A333

| Element |

Grade 3 |

Grade 6 |

| C |

0.19 |

0.30 |

| Mn |

0.31–0.64 |

0.29–1.06 |

| P |

0.025 |

0.025 |

| S |

0.025 |

0.025 |

| Si |

0.18–0.37 |

0.10 min |

| Ni |

3.18–3.82 |

0.40 |

| Cr |

… |

0.30 |

| Cu |

… |

0.40 |

| Al |

… |

… |

| V |

… |

0.08 |

| Cb |

… |

0.02 |

| Mo |

… |

0.12 |

| Co |

… |

… |

CS Welded and Seam Pipe mechanical properties

ASTM A53

| Seamless and ERW |

A53 Grade B |

A53 Grade A |

| Yield Strength |

35,000 |

30,000 |

| Tensile Strength, min, psi |

60,000 |

48,000 |

ASTM A106

| ASTM A106 |

Grade A |

Grade B |

Grade C |

| Yield Strength, min., psi |

30,000 |

35,000 |

40,000 |

| Tensile Strength, min., psi |

48,000 |

60,000 |

70,000 |

ASTM A333